Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

List some important industry finished products used in the high-temperature vacuum furnace

When we mentioned the high-temperature vacuum furnace, the related Tungsten isolation screen should be paid attention to have a talk here. Manufactured by pure tungsten material, the Tungsten material is a kind of refractory metal. It has the characteristics of high melting point (3410℃), high density (19.35g/cm3), high hardness, high strength, low thermal expansion coefficient, good heat resistance and good corrosion resistance. The overall performance of the produced thermal insulation components is better, which is mainly manifested in good heat-proof effect, strong heat resistance and long service life, that is, in the environment of thousands of degrees Celsius, the component is not easy to deform.

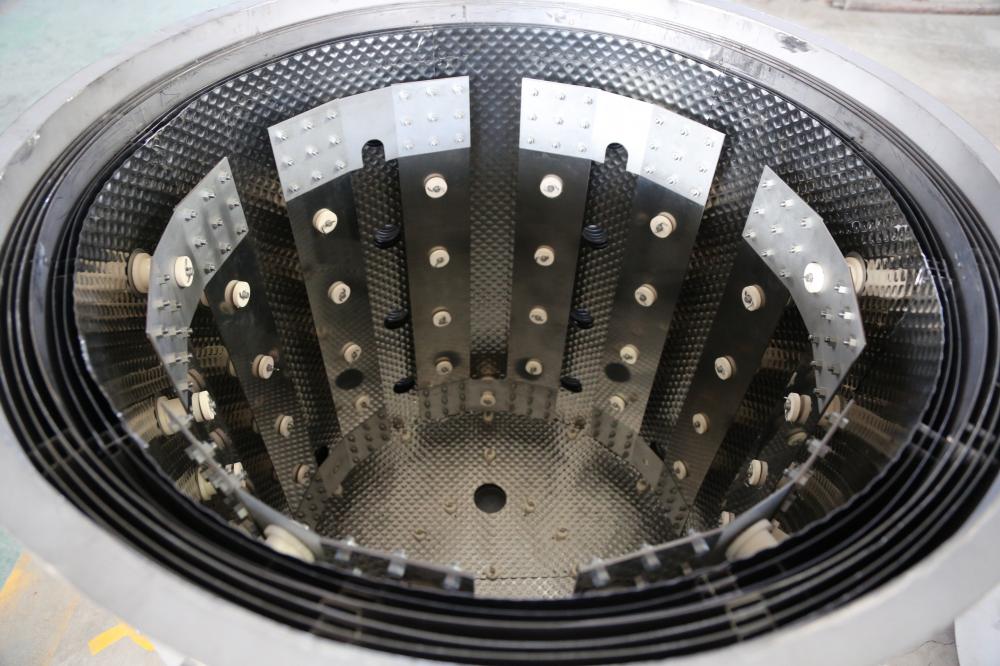

Molybdenum heat shield or tungsten heat shield is generally made by riveting, which can be butted or overlapped. Corrugated plates, U-shaped grid bars or spacer rings can be used between each layer of screens, and they are fixed with molybdenum or tungsten wires and screws. It is worth noting that when the temperature is higher than 500 ℃ in the air, tungsten will oxidize rapidly, and when the temperature is higher than 400 ℃, molybdenum will also oxidize, so the molybdenum parts and tungsten parts should be in vacuum or inert atmosphere. use in the environment.

In addition to molybdenum heat shields, the side screens and upper and lower cover screens of the vacuum furnace can also be produced with tungsten heat shields. Compared with thermal insulation components made of other materials, components made of tungsten and molybdenum materials have better thermal protection and can block thermal convection more effectively.

Molybdenum is also a refractory metal with a density of 10.23g/cm3, which is about half of that of tungsten. It has the characteristics of high melting point (2622°C), high hardness, low thermal expansion coefficient and resistivity, so it is often used to produce long-term high temperature Thermal insulation components that work in ambient conditions.

There are some tungsten and molybdenum parts used in high-temperature vacuum furnace such as mesh heater, molybdenum wire and tungsten twisted wire.

July 03, 2023

Mail an Lieferanten

July 03, 2023

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.